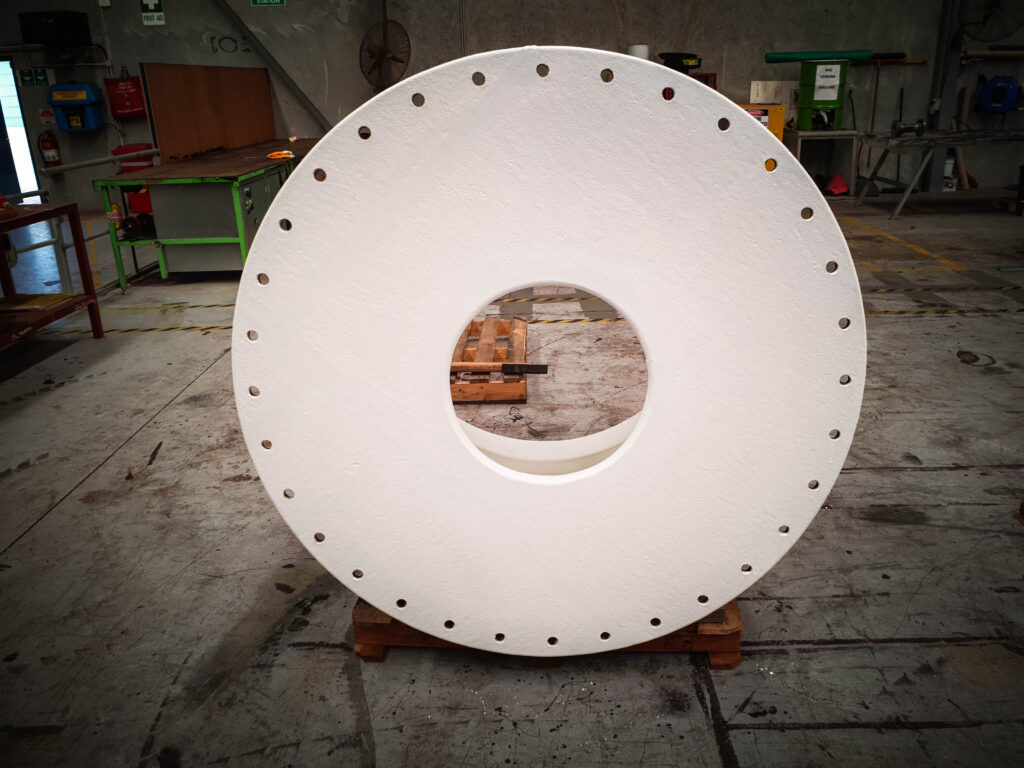

Rubber Lining

SURFACE LINING PROTECTION FOR YOUR PLANT AND EQUIPMENT

Rubber and ceramic lining provides improved productivity by reducing wear and corrosion on plant and infrastructure.

At VLI Conveyors our extensive rubber lining experience includes protecting chutes, pipes, tanks, large vessels and pulley lagging.

Rubber lining can be categorised into two main groups –

Cold: Generally a 2-part adhesive is used to bond wear and chemical resistant rubber sheet to steel work. This process can be done either onsite or in our workshops.

Hot: Vessels and pipes are lined in raw (uncured) rubber which is subsequently cured in an autoclave or using open steam curing (where the vessel acts as the autoclave). Vulcanising rubber to an item produces a seamless lining to covering eliminating adhesive joins associated with cold bonding and generally gives higher bond strength and temperature resistance. Hot bonding is recommended for chemical reaction vessels and abrasive slurry handling applications as it has superior durability when compared to cold bonding.